Expanded Review and Implementation Strategy: Sustainable Organic Waste Management in Poultry Farms Using the BiobiN® System

Dr. Majed Hamed Al Saegh / poultry pathologist / Australia

- Introduction

The intensification of poultry farming has significantly increased the volume of organic waste produced worldwide. Mortality events, manure, litter, feathers, and spoiled feed are among the many by-products that, if not managed properly, contribute to environmental degradation, disease outbreaks, and public health threats. In many regions, particularly in the Global South and high-density production zones, the management of this waste remains rudimentary, with methods like burial, incineration, or landfilling still in use. These methods not only emit methane—a potent greenhouse gas—but also risk groundwater contamination, soil degradation, and pathogen proliferation (FAO, 2021; IPCC, 2014).

Modern poultry operations are now expected to align with One Health principles, circular economy models, and environmental protection frameworks. There is an urgent need for practical, scalable solutions that integrate waste reduction, pathogen control, and resource recovery. Among the most promising systems is BiobiN®, a patented on-site composting and containment solution originally developed by Peats Soil and Garden Supplies in South Australia. The BiobiN® offers a modular, environmentally sound method of managing poultry waste that satisfies the demands of biosecurity, efficiency, and sustainability.

- System Overview and Technical Advantages

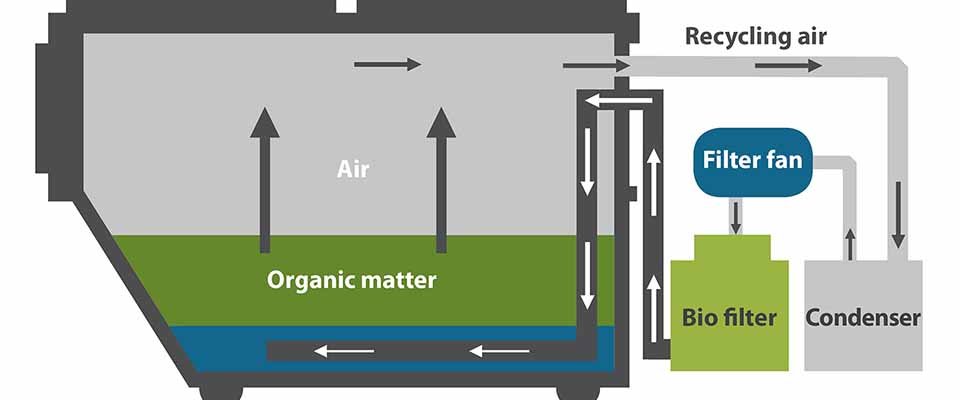

2.1 How BiobiN® Works : The BiobiN® system is a fully enclosed vessel that uses forced aeration and biofiltration to initiate aerobic composting of organic materials. This process begins immediately upon loading, reducing odours and pathogen survival through elevated internal temperatures and the production of ammonia. The vessel maintains optimal conditions for microbial decomposition, ensuring that the waste is pre-processed before it is transported to a final composting site—or fully composted in the case of the 2.0 FTM self-service unit.

2.2 Technical Specifications

| Model | Footprint (L×W) Net Weigh | Capacity | Gross Weight |

| 2.0 m³ (FTM) | 3.5 × 3 m | 500 kg 1,450 kg | 1,950 kg |

| 4.5 m³ | 3.2 × 3 m | 650 kg 3,000 kg | 3,650 kg |

| 9.0 m³ | 4.5 × 4 m | 1,000 kg 7,500 kg | 8,500 kg |

| 20.0 m³ | 8 × 2.5 m | 4,000 kg 16,000 kg | 20,000 kg |

Add-on features include hydraulic lids, tippler bins, wheels, lifting units, and off-grid power options, enhancing safety and usability.

- Scientific Validation and Pathogen Control

Studies conducted by Flinders University (2007) validated the BiobiN® system’s ability to rapidly reduce pathogen loads, with E. coli and Salmonella typhimurium levels dropping to below detectable limits within a short time. This is achieved through a combination of sustained high temperatures and ammonia production during decomposition. Such results are critical for poultry farms where disease containment is essential for preventing regional outbreaks of avian influenza, Newcastle disease, and bacterial enteritides.

- Environmental and Regulatory Alignment, BiobiN® directly addresses global environmental targets:

- Greenhouse Gas Reduction: Diverts organic material from landfills, preventing methane generation.

- Circular Economy: Converts waste into usable compost or soil enhancers.

- Sustainable Development Goals (SDGs): Aligns with SDG 12 (Responsible Consumption and Production), SDG 13 (Climate Action), and SDG 3 (Good Health and Well-being).

- Compliance with National Biosecurity Standards: Meets guidelines from the OIE and national regulators for mortality management and disease control.

- Implementation Strategies in Poultry Systems

5.1 On-Farm Integration

BiobiN® can be incorporated as a central mortality management hub on large farms or used as mobile units for medium-scale facilities. The 2.0 FTM is ideal for remote or resource-limited farms, requiring only a forklift for bin handling. For larger operations, the 9.0 or 20.0 m³ units can be placed near bird sheds, with regular collection of pre-composted waste to central facilities.

5.2 Regional Collection Systems

Clusters of farms can collaborate in shared BiobiN® hubs with scheduled waste pickup, reducing costs and improving composting throughput. Municipalities or cooperatives can own the central composting site while providing BiobiN® units to contract growers or smallholder farms.

5.3 Emergency Disease Control

BiobiN® is especially suited to high-risk periods such as AI outbreaks. The sealed vessel ensures that infected mortalities are biosecurely held and decomposed without external exposure, preventing spread via scavengers, surface runoff, or aerosolisation. This supports emergency containment protocols for notifiable diseases.

5.4 Institutional and Commercial Use

- The system is scalable for use in:

- Hatcheries and abattoirs

- Veterinary schools and research stations

- Commercial composting facilities

- Government-led biosecurity programs

- Global Case Studies and Adoption

Australia: Widely adopted across turkey and broiler operations in South Australia, including successful integration with Inghams Growers.

Japan: Used in post-Fukushima recovery zones to manage organic farm waste safely under restricted conditions.

Middle East & Asia: Demonstrated value in arid environments where composting conditions are hard to control manually.

- Challenges and Recommendations

Challenges

- Initial capital cost may be a barrier for smallholders without government or cooperative support.

- Requires minimal training on aeration settings and moisture balance for optimal performance.

- In some countries, compost regulations may need to be updated to fully support decentralised models.

Recommendations

- Subsidies or grants should be provided to encourage adoption among small and medium farms.

- Training programs and extension services are critical for uptake.

- Governments and development agencies should include BiobiN®-type systems in climate-smart agriculture policies.

- Conclusion

The BiobiN® system represents a paradigm shift in how poultry operations can manage their organic waste. It offers an environmentally sound, biosecure, and economically practical solution that addresses key challenges in waste handling, disease containment, and resource recovery. As global agriculture faces the twin pressures of climate change and increased demand for sustainable protein production, systems like BiobiN® provide a scalable and science-backed tool to transition towards safer, cleaner, and circular food production systems.